Engineered with precision

We believe in taking pride in making things by our own hands, which is the literal meaning of manufacturing. So we make loopwheels ourselves, by hand, in Nottinghamshire.

We are proud that the springs are made just a few miles from where the loopwheel was invented, and that we assemble our wheels in Nottinghamshire too.

We care about nurturing creativity, our engineering skills, and manufacturing. We are not nostalgic or sentimental about it, we just believe in making and doing, and making and doing it well.

What are loopwheels made from?

More about loops

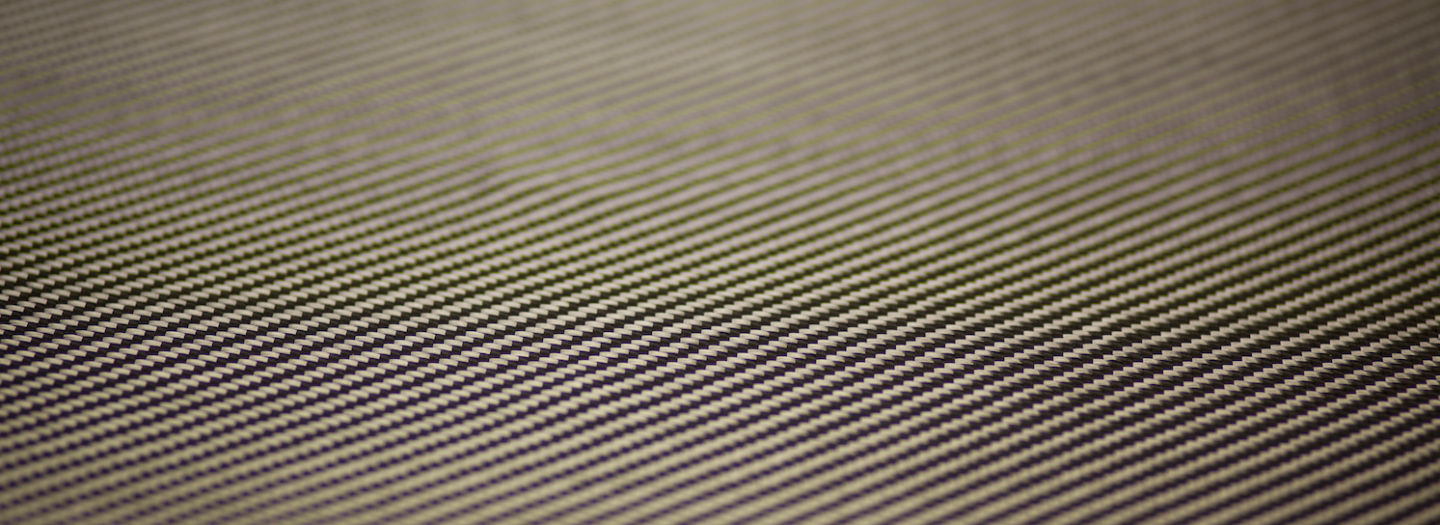

These are leaf springs made from a carbon composite, which we have developed specifically for loopwheels. They are strong and durable. We use different formulations of composites to give different compression rates and spring rates.

Where can I find out more?

General information is on our About Loopwheels page. We try to provide as much specific product info as possible on each product page. If you have a question we haven’t answered in any of these places, try our FAQs or drop us an email at [email protected].

Components

The springs are a carbon fibre composite material.

Hubs, rim connectors and hub connectors on Loopwheels Classics are die-cast aluminium. On our second generation Loopwheels (Urban, LT and Extreme) these are machined aluminium.

All Loopwheels rims are aluminium. Push rim materials vary according to model.

Technical information

The specification for each model of Loopwheel can be found on the product page and in our user manuals.

Our Custom Built Testing Environment

The development of loopwheels took more than 4 years before the public launch in 2013.

Sam Pearce is the inventor of Loopwheels. He has a degree in mechanical engineering, and a masters degree in Industrial Design for Engineers.

Sam put loopwheels through extensive research and development. He first used an external, independent test house to verify the prototype loopwheel. We later invested in test machinery in our own facilities, to ensure we continue to meet high standards of technical performance and safety.

Our test programme comprises mechanical testing on test machines, and real-life off-road riding and user evaluation.

Each time we introduce a new variant of wheel, for example, we put it on a rolling road machine for 10,000 miles before we are satisfied that it offers durability for our customers. We test for impact at high velocity as well.

We continue to test our wheels to assure the quality of each product and of every new product development. We code every wheel to identify it with a unique serial number. We want you to have a lifetime of enjoyment with loopwheels, so we build each one with precision.

Our second generation of Loopwheels can be used for seated passenger transport in a vehicle and a copy of the certificate for this test from Cranfield Impact Centre is downloadable here.